Master the art of preparing a Bar Bending Schedule (BBS). Our step-by-step guide for civil engineers and site supervisors covers formulas, standards, and best practices to control reinforcement costs and ensure structural safety.

The Blueprint for Steel: How to Prepare a Bar Bending Schedule (BBS)

In the world of reinforced concrete, the structural drawings show you where the rebar goes, but the Bar Bending Schedule (BBS) tells you exactly how to shape it, how much to order, and how to manage it on site. It’s the critical link between design and execution, transforming abstract lines on a drawing into a precise list of cut and bent steel.

A well-prepared BBS is not just a paperwork exercise; it’s a powerful tool for cost control, waste minimization, and quality assurance. This guide will walk you through the process of creating one from scratch.

What is a Bar Bending Schedule (BBS)?

A Bar Bending Schedule is a comprehensive list that describes the location, mark, size, length, quantity, and shape of all reinforcing bars for a concrete element. It’s essentially a shopping and fabrication list for the rebar.

Why is it so Important?

- Minimizes Waste: Precise calculations reduce cutting waste, saving significant material costs.

- Improves Efficiency: Steel can be pre-fabricated off-site, speeding up the construction process.

- Ensures Accuracy: Eliminates guesswork for the bar benders, ensuring the right bars are in the right place.

- Aids in Estimation: Provides an exact bill of quantity for tendering and procurement.

Key Terminology You Must Know

Before we start, let’s get familiar with the standard terms and abbreviations used in a BBS:

- Bar Mark: A unique reference number (e.g., B1, M5) for each distinct type of bar in the schedule.

- Dia. (Diameter): The bar’s diameter in mm (e.g., 10mm, 16mm).

- Shape: A graphical representation or code (from standards like BS 8666) showing the bar’s bent form.

- Length (A, B, C…): The straight portions of a bent bar, used to calculate the total length.

- No. of Bars: The total quantity of bars for that specific mark.

- Total Length: The sum of the cut lengths for all identical bars.

- Weight per Meter: The unit weight of the bar based on its diameter.

- Total Weight: The total weight for all bars of that mark.

Step-by-Step Guide to Preparing a BBS

Let’s prepare the BBS for a simple concrete beam. We’ll assume the beam is 300mm wide x 450mm deep and 5000mm long.

Step 1: Gather the Necessary Documents

- Structural Drawings: Including reinforcement details, sections, and plans.

- Relevant Design Codes: Such as ACI 318, IS 456, or BS 8110 for lap lengths, bend deductions, and cover requirements.

- Standard Shape Codes: A reference for bar bending shapes (e.g., BS 8666).

Step 2: Identify the Structural Element

Start with one element at a time (e.g., a beam, column, or slab). For our example, we’ll focus on Beam B1.

Step 3: Decipher the Reinforcement Details from the Drawing

From the beam detailing drawing, we identify:

- Bottom Reinforcement: 3 bars of 16mm diameter.

- Top Reinforcement: 2 bars of 12mm diameter.

- Stirrups (Shear Reinforcement): 8mm diameter bars @ 150mm c/c (center-to-center) spacing.

- Concrete Cover: 25mm to all sides.

- Lap Length for bottom bars: Assume 50 times the diameter (50d) as per the code.

Step 4: Calculate the Cutting Length for Each Bar

This is the most crucial step. The cutting length is the total length of a straight bar before it is bent.

A. Calculate for Bottom Bars (Mark B1)

- Given: Clear Span = 5000mm, Cover = 25mm on both ends.

- Formula: Cutting Length = Clear Span + (2 x Development Length) – (2 x Bend Deduction for 90° bends)

- Simplified Practical Approach:

- Cutting Length = Clear Span + 2 x Cover (if no development length is shown at ends)

- But our drawing specifies a lap length at the supports. Let’s assume the development length is provided and the bar runs from the face of one column to the face of the other.

- A more accurate calculation:

- Cutting Length = (Cover at Start) + (Width of Column at Start) + (Clear Span) + (Width of Column at End) + (Cover at End) – (Bend Deductions at columns)

- For simplicity in this example, let’s use:

- Cutting Length = 5000mm + (2 x 150mm) = 5300mm. (Assuming 150mm engagement into the columns on each side).

B. Calculate for Stirrups (Mark S1)

- Given: Beam Width = 300mm, Beam Depth = 450mm, Cover = 25mm.

- Formula for Stirrup Cutting Length:

- = 2*(a + b) + 24d (for 135° hooks as per standard practice) – (Bend Deductions)

- Where ‘a’ & ‘b’ are the inner dimensions of the stirrup.

- Calculate a & b:

- a = Width – 2 x Cover = 300 – 2*25 = 250mm

- b = Depth – 2 x Cover = 450 – 2*25 = 400mm

- Hook Length: For a 135° hook, length is often taken as 16d (or as per code).

- Practical Formula (with 135° hooks):

- Cutting Length = 2*(a + b) + 2 * Hook Length – 3 * (2d) Bend Deduction

- = 2(250 + 400) + 2(168) – 3(16)

- = 2*(650) + 256 – 48

- = 1300 + 256 – 48 = 1508mm

C. Calculate Number of Stirrups

- Given: Spacing = 150mm c/c, Clear Span = 5000mm.

- Formula: Number of Stirrups = (Clear Span / Spacing) + 1

- Calculation: = (5000 / 150) + 1 = 33.33 + 1 = 34.33 → Round up to 35 Nos.

Step 5: Create the Bar Bending Schedule Table

Now, we compile all the calculated data into a clean, organized table.

Bar Bending Schedule for Beam B1

| Bar Mark | Dia. (mm) | Shape | No. of Bars | Length (mm) | Total Length (m) | Weight/m (kg/m) | Total Weight (kg) |

|---|---|---|---|---|---|---|---|

| B1 | 16 | ![Straight Bar] | 3 | 5300 | 15.9 | 1.58 | 25.12 |

| T1 | 12 | ![Straight Bar] | 2 | 5300 | 10.6 | 0.89 | 9.43 |

| S1 | 8 | ![Stirrup Shape] | 35 | 1508 | 52.78 | 0.39 | 20.58 |

| Grand Total Weight → | 55.13 kg |

Note: The “Weight per Meter” for steel is calculated as (D² / 162) for metric units, where D is the diameter in mm. E.g., for 16mm bar: (16² / 162) = 1.58 kg/m.

Best Practices and Pro Tips

- Standardize Bar Marks: Use a consistent numbering system (e.g., B1, B2 for beams; S1, S2 for stirrups) across the entire project.

- Consider Practicality: The total length of a bar should generally not exceed 12 meters, as this is a standard stock length. Use lap splices where necessary.

- Account for Wastage: Add a wastage factor (typically 3-5%) to the final total weight when ordering.

- Software is Your Friend: While manual calculation is essential for learning, use BBS software (like AutoCAD, Revit, or specialized tools) for large projects to improve speed and accuracy.

- Double-Check Everything: A simple error in a single bar mark can lead to hundreds of incorrectly fabricated bars. Have a second engineer or checker review the schedule.

When to Use a BBS

A Bar Bending Schedule is prepared for every reinforced concrete element:

- Slabs

- Beams

- Columns

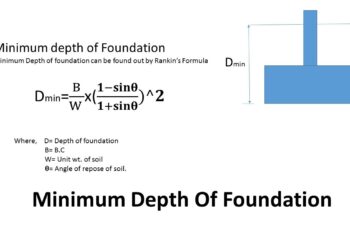

- Foundations (Footings, Pile Caps)

- Retaining Walls

Referrals for Further Reading

- “SP 34: Handbook on Concrete Reinforcement and Detailing”

- What it is: An Indian Standard that serves as an excellent guide for best practices in reinforcement detailing and BBS preparation.

- Best for: Comprehensive understanding of detailing standards.

- “CRSI Manual of Standard Practice”

- What it is: The U.S. industry standard from the Concrete Reinforcing Steel Institute.

- Best for: Learning American standards and practices for rebar shaping, placing, and scheduling.

- IS 2502: Code of Practice for Bending and Fixing of Steel Reinforcement

- What it is: An Indian Standard that provides guidelines specifically for the bending and fixing process, which is directly related to BBS.

- Best for: Understanding the practical implementation of a BBS on site.

Conclusion: From Paper to Practice

Preparing a Bar Bending Schedule is a fundamental skill for any civil engineer, detailer, or site supervisor. It translates the theoretical design into an actionable, efficient, and cost-effective plan for construction. By mastering the steps outlined above—from interpreting drawings to performing precise calculations—you ensure that the skeleton of your structure is built with integrity, economy, and precision. Remember, a great building starts with a great BBS.