Concrete is one of the most widely used construction materials in the world. Its versatility, strength, and durability make it ideal for a variety of construction projects, from small residential buildings to large infrastructure works. However, the quality of concrete largely depends on the correct mix ratio of its components: cement, sand, aggregate, and water. Understanding how to calculate the concrete mix ratio is crucial for ensuring the strength, durability, and workability of the concrete.

In this comprehensive guide, we will explore everything you need to know about calculating concrete mix ratios for construction projects. We will cover the basics of concrete composition, types of concrete mixes, factors affecting mix design, step-by-step calculation methods, and practical tips for achieving the best results on your site.

Table of Contents

- Introduction to Concrete Mix Ratio

- Components of Concrete

- Importance of Concrete Mix Ratio

- Common Types of Concrete Mix Ratios

- Factors Affecting Concrete Mix Design

- Step-by-Step Guide to Calculate Concrete Mix Ratio

- Practical Examples of Concrete Mix Calculation

- Tips for Mixing Concrete

- Quality Control and Testing of Concrete Mix

- Conclusion

1. Introduction to Concrete Mix Ratio

The concrete mix ratio refers to the proportion of the four main ingredients of concrete: cement, sand (fine aggregate), coarse aggregate, and water. These proportions determine the concrete’s strength, durability, and usability. The mix ratio is often expressed in terms of volume or weight, such as 1:2:4, which means 1 part cement, 2 parts sand, and 4 parts coarse aggregate.

Correctly calculating and maintaining the mix ratio is vital to achieving the desired properties of concrete for a specific project. An improper mix can lead to weak concrete, cracking, poor setting, or other failures.

2. Components of Concrete

Before diving into mix ratios, it’s essential to understand the role of each component in concrete:

- Cement: Acts as a binder that holds all the other components together. Portland cement is the most commonly used type.

- Sand (Fine Aggregate): Provides bulk and strength to the concrete. It fills the gaps between coarse aggregates.

- Coarse Aggregate: Usually gravel or crushed stone, it provides compressive strength and volume.

- Water: Initiates the chemical reaction with cement (hydration) and provides workability. The water/cement ratio significantly influences strength.

Additional materials such as admixtures, fly ash, or slag can be added for specific properties but are beyond the scope of this basic guide.

3. Importance of Concrete Mix Ratio

The concrete mix ratio affects:

- Strength: A higher cement content typically increases strength.

- Workability: Water and fine aggregates influence how easy the concrete is to place and finish.

- Durability: Proper proportions help resist environmental factors like freezing, thawing, and corrosion.

- Economy: Efficient use of materials reduces costs while maintaining quality.

4. Common Types of Concrete Mix Ratios

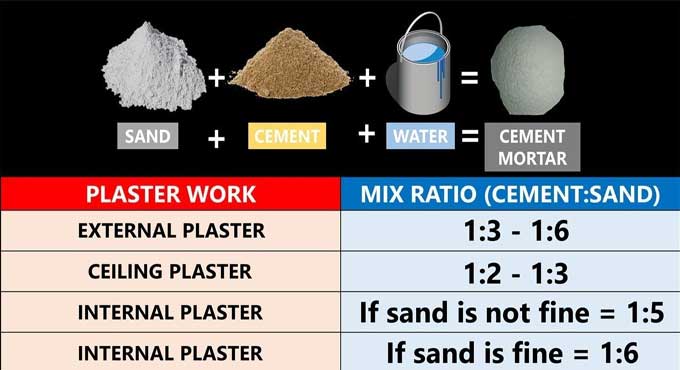

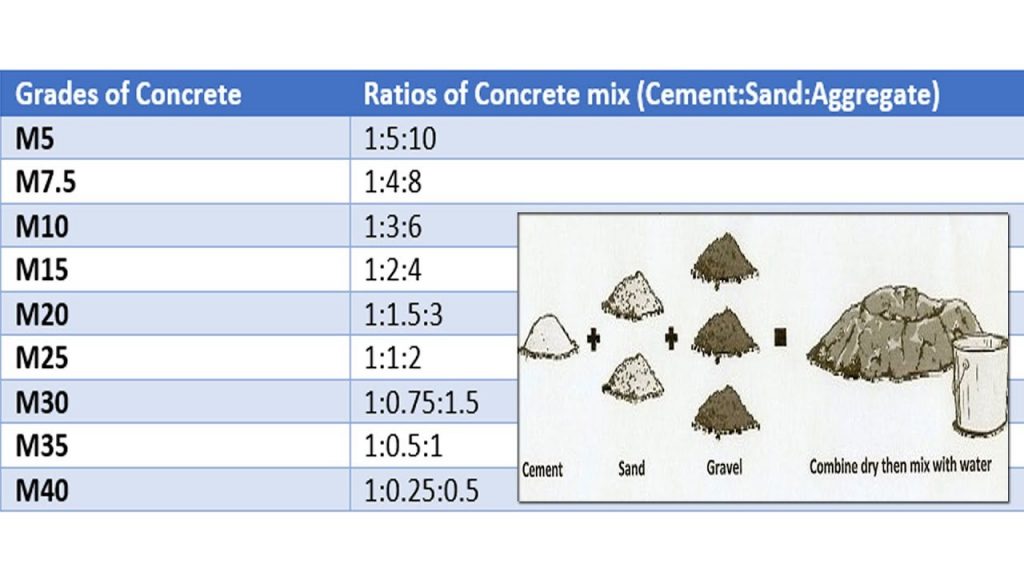

Here are some typical concrete mix ratios expressed as Cement:Sand:Coarse Aggregate:

- 1:2:4 – Used for foundations and reinforced concrete works.

- 1:1.5:3 – Suitable for structural concrete with higher strength.

- 1:3:6 – Used for plain concrete works like flooring or pathways.

- 1:1:2 – For high-strength concrete.

Note that these ratios can vary based on the project needs and standards of the region.

5. Factors Affecting Concrete Mix Design

Several factors influence the choice and calculation of the concrete mix ratio:

- Required Compressive Strength: Higher strength demands more cement.

- Workability: Desired ease of placing concrete affects water and fine aggregate content.

- Size and Type of Aggregate: Larger aggregates reduce cement demand.

- Durability Requirements: Exposure conditions might require specific mix proportions.

- Water-Cement Ratio: Lower water content increases strength but reduces workability.

- Type of Cement and Admixtures: Different cements and additives can modify mix requirements.

- Environmental Conditions: Hot or cold weather can affect setting times and water needs.

6. Step-by-Step Guide to Calculate Concrete Mix Ratio

Step 1: Determine Design Strength

Consult project specifications or standards (e.g., ACI, IS codes) to identify the required compressive strength at 28 days.

Step 2: Choose the Mix Ratio

Based on strength and workability requirements, select a preliminary mix ratio. For example, 1:2:4 is common for M20 concrete (20 MPa strength).

Step 3: Calculate Material Quantities for 1 Cubic Meter of Concrete

Concrete volume = 1 m³ (for calculation convenience)

Step 3.1: Calculate the total parts of the mix

Add the ratio parts: 1 (cement) + 2 (sand) + 4 (aggregate) = 7 parts

Step 3.2: Calculate the volume of each material

Volume of cement = (1/7) × 1 m³ = 0.1429 m³

Volume of sand = (2/7) × 1 m³ = 0.2857 m³

Volume of aggregate = (4/7) × 1 m³ = 0.5714 m³

Step 3.3: Adjust for the dry volume

Since the concrete mix components are in dry form, allow for 10-15% extra volume to account for voids and shrinkage.

Dry volume = 1.54 × 1 m³ = 1.54 m³ (assuming 54% bulking factor)

New volumes:

Cement = 0.1429 × 1.54 = 0.22 m³

Sand = 0.2857 × 1.54 = 0.44 m³

Aggregate = 0.5714 × 1.54 = 0.88 m³

Step 3.4: Convert volume of materials to weight

Use density values:

- Cement: ~1440 kg/m³

- Sand: ~1600 kg/m³

- Aggregate: ~1450 kg/m³

Calculate weights:

Cement weight = 0.22 × 1440 = 316.8 kg

Sand weight = 0.44 × 1600 = 704 kg

Aggregate weight = 0.88 × 1450 = 1276 kg

Step 3.5: Calculate water quantity

Water-cement ratio typically ranges from 0.4 to 0.6. For M20 concrete, assume 0.5.

Water weight = 0.5 × cement weight = 0.5 × 316.8 = 158.4 kg

Water volume = 158.4 / 1000 = 0.1584 m³ (since 1 liter = 1 kg of water)

7. Practical Examples of Concrete Mix Calculation

Example 1: Calculate material quantities for 5 m³ of M15 concrete with a mix ratio of 1:2:4

- Total parts = 7

- Dry volume = 5 × 1.54 = 7.7 m³

Volume of cement = (1/7) × 7.7 = 1.1 m³

Volume of sand = (2/7) × 7.7 = 2.2 m³

Volume of aggregate = (4/7) × 7.7 = 4.4 m³

Weights:

Cement = 1.1 × 1440 = 1584 kg

Sand = 2.2 × 1600 = 3520 kg

Aggregate = 4.4 × 1450 = 6380 kg

Water (w/c = 0.6):

Water = 0.6 × 1584 = 950 kg or 950 liters

Example 2: Adjusting mix for workability

If the concrete is too stiff, increase water content slightly, but keep water-cement ratio under control to maintain strength.

8. Tips for Mixing Concrete

- Use accurate measurement tools or scales for materials.

- Mix dry ingredients thoroughly before adding water.

- Add water gradually to achieve desired workability.

- Avoid excess water to prevent weak concrete.

- Use clean water and aggregates free from impurities.

- If mixing manually, use a wheelbarrow or mixing tray.

- For large projects, use a concrete mixer.

9. Quality Control and Testing of Concrete Mix

- Conduct slump tests to check workability.

- Use compressive strength tests on cubes or cylinders after 7 and 28 days.

- Monitor curing conditions to prevent drying too fast.

- Adjust mix ratios based on test results and site conditions.

10. Conclusion

Calculating the concrete mix ratio correctly is fundamental to the success of any construction project involving concrete. By understanding the components, their roles, and the factors influencing mix design, you can tailor the concrete mix to meet specific strength, durability, and workability requirements.

Always start with the project specifications and standards, calculate the quantities carefully, and verify the mix through testing. With proper planning and execution, you can ensure your concrete structure stands the test of time.

References

- IS 456:2000 – Code of Practice for Plain and Reinforced Concrete

- ACI 211.1 – Standard