Concrete is one of the most widely used construction materials in the world, known for its strength, durability, and versatility. However, to achieve its full potential, concrete must undergo a process called curing. Proper curing is essential for the concrete to reach its desired strength and durability, ensuring the longevity and safety of the structures built with it. In this blog post, we will explore the importance of curing concrete and the various methods used to do it effectively.

What is Curing Concrete?

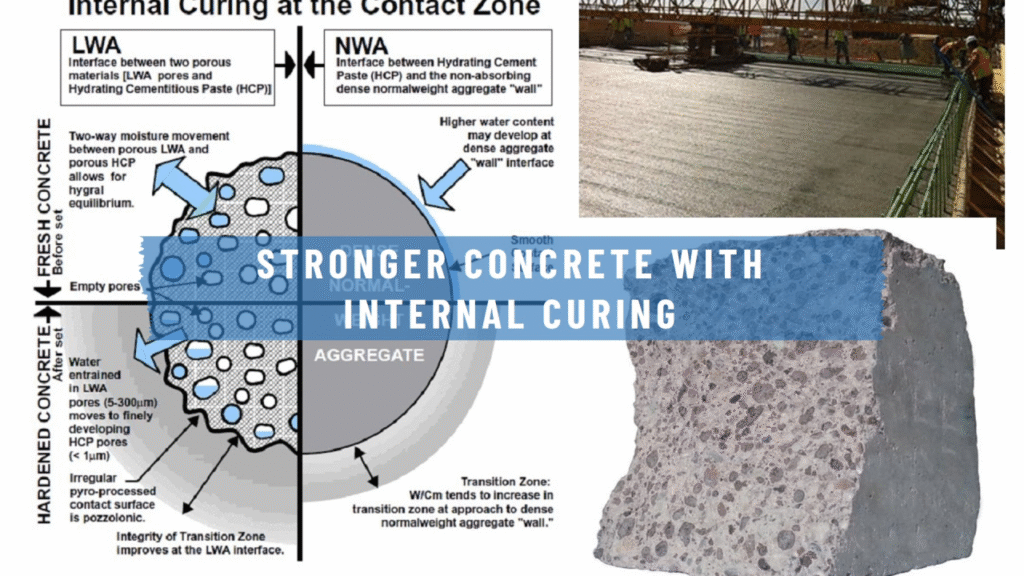

Curing is the process of maintaining adequate moisture, temperature, and time to allow freshly placed concrete to achieve its desired properties. When concrete is mixed and poured, it undergoes a chemical reaction called hydration, where water reacts with cement to form a hard, solid mass. This reaction needs sufficient moisture and time to continue effectively; otherwise, the concrete can dry out too quickly, leading to weak, brittle, and cracked surfaces.

Why is Curing Concrete Important?

- Strength Development

Proper curing ensures that the hydration process continues uninterrupted, enabling the concrete to develop maximum strength. Without adequate curing, the concrete’s strength can be significantly reduced, compromising the structural integrity. - Durability and Longevity

Cured concrete is less permeable to water and chemicals, which helps resist weathering, corrosion, and chemical attacks. This enhances the durability and lifespan of the structure. - Prevention of Cracking

Rapid moisture loss during the initial stages can cause shrinkage cracks. Curing helps maintain moisture levels, reducing the risk of surface cracks and improving the overall finish. - Improved Surface Quality

Properly cured concrete has a denser surface, which reduces dusting and wear, making it more suitable for floors, pavements, and decorative finishes. - Reduced Permeability

Curing minimizes the pore size in the concrete, making it less permeable to water and harmful agents, which is crucial in environments exposed to freeze-thaw cycles or chemical exposure.

How is Concrete Cured?

There are several methods used to cure concrete, and the choice depends on the type of structure, environmental conditions, and available resources. Here are the most common curing methods:

1. Water Curing

Maintaining a wet surface ensures continuous hydration. This can be done by:

- Ponding or Immersion: Suitable for flat surfaces, water is ponded on the concrete for a specific duration.

- Spraying or Fogging: Water is sprayed over the surface continuously or intermittently to keep it moist.

- Wet Coverings: Using wet burlap, mats, or cotton mats that are kept continuously wet to cover the concrete.

2. Membrane Curing

This involves applying a curing compound or membrane to the concrete surface that forms a film, preventing moisture loss. It is often used when water curing is impractical.

3. Covering with Plastic Sheets

Plastic sheets or polyethylene films are placed over the fresh concrete to trap moisture and prevent evaporation. This method is simple and effective, especially in dry or windy conditions.

4. Steam Curing

Used mainly in precast concrete production, steam curing accelerates the hydration process by exposing concrete to controlled heat and humidity.

5. Insulating Blankets

In cold weather, insulating blankets or heated enclosures are used to maintain temperature and protect concrete from freezing while curing.

Duration of Curing

The curing period varies depending on the mix, environmental conditions, and the type of cement used. Typically, concrete should be cured for at least 7 days to achieve adequate strength, but in some cases, curing for 14 to 28 days is recommended for optimal results. For high-performance concrete, curing times may be longer.

Conclusion

Curing is a critical step in the concrete construction process that significantly influences the strength, durability, and overall quality of the finished structure. Neglecting proper curing can lead to premature failures, increased maintenance costs, and safety hazards. By understanding the importance of curing and implementing effective curing methods, builders and engineers can ensure that their concrete structures stand the test of time. Always consider the environmental conditions and specific project requirements when selecting a curing method to achieve the best possible outcome.