Calculating the quantity of steel required for a slab is a crucial step in construction project planning. Accurate estimation helps in budgeting, procurement, and ensuring structural integrity. This blog post will guide you through the process of calculating the quantity of steel in a slab efficiently.

Understanding the Basics

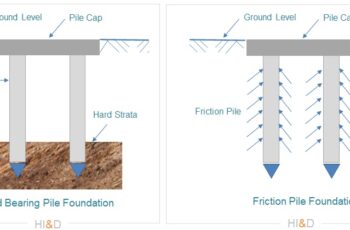

A slab in construction is a flat horizontal surface, typically made of concrete, reinforced with steel bars (rebar) to withstand tensile stresses. The steel quantity depends on slab thickness, dimensions, and reinforcement details.

Key Terms:

- Slab Thickness (t): Depth of the slab, usually in millimeters (mm).

- Slab Area (A): Length × Width of the slab, in square meters (m²).

- Steel Reinforcement Percentage (p): The percentage of steel by volume or weight specified by structural design.

- Density of Steel: Approximately 7850 kg/m³.

Step-by-Step Guide to Calculate Steel Quantity

Step 1: Determine the Slab Dimensions

Measure or obtain the slab length, width, and thickness. For example:

- Length (L) = 5 meters

- Width (W) = 4 meters

- Thickness (t) = 0.15 meters (150 mm)

Step 2: Calculate the Volume of Concrete in the Slab

Volume ( V ) is calculated as:

[

V = L \times W \times t

]

Using our example:

[

V = 5 \times 4 \times 0.15 = 3 \, m^3

]

Step 3: Identify the Steel Reinforcement Percentage

The steel percentage depends on the design and type of slab. Common values range from 0.8% to 1.2%. Assume a steel percentage of 1% (0.01) for this example.

Step 4: Calculate the Volume of Steel

The volume of steel ( V_s ) is:

[

V_s = p \times V

]

[

V_s = 0.01 \times 3 = 0.03 \, m^3

]

Step 5: Convert Steel Volume to Weight

Using steel density (7850 kg/m³):

[

W_s = V_s \times 7850 = 0.03 \times 7850 = 235.5 \, kg

]

Thus, approximately 235.5 kg of steel is required for the slab.

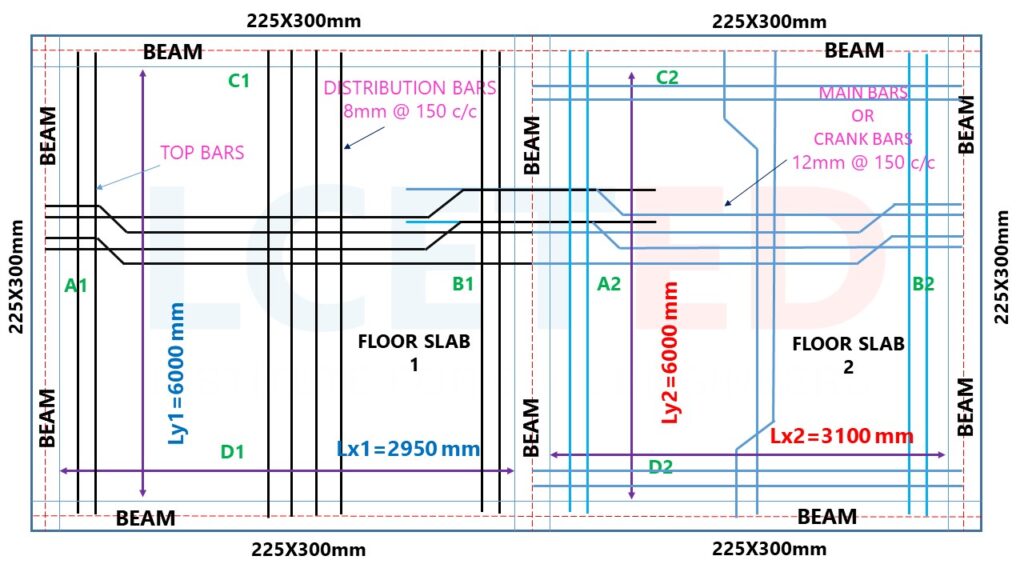

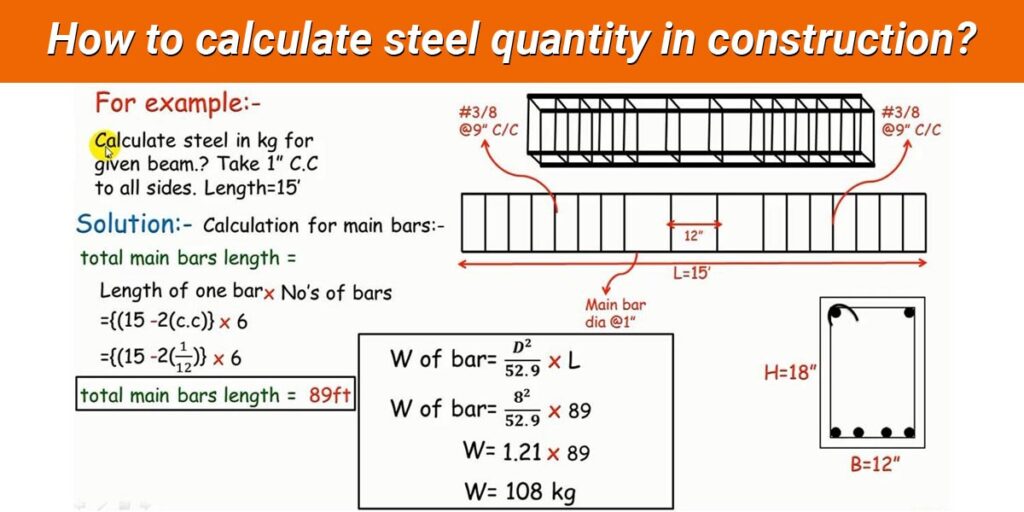

Alternative Method: Using Steel Bar Sizes and Spacing

If you have detailed reinforcement drawings specifying bar diameter and spacing, follow these steps:

- Calculate the number of bars:

[

\text{Number of bars} = \frac{\text{Slab width}}{\text{Bar spacing}}

] - Calculate length of each bar:

Usually equal to slab length plus allowances for anchorage. - Calculate total length of steel:

[

\text{Total length} = \text{Number of bars} \times \text{Length of each bar}

] - Calculate weight per unit length for each bar size:

Use standard weight charts (e.g., for 12 mm diameter, weight is 0.888 kg/m). - Calculate total steel weight:

[

\text{Total weight} = \text{Total length} \times \text{Weight per unit length}

]

Repeat the process for bars in both directions and sum the weights.

Important Tips

- Always include a wastage factor (usually 2-3%) to account for cutting and overlaps.

- Consult structural drawings for precise steel percentages and bar sizes.

- Double-check calculations to avoid material shortages or excess.

Conclusion

Calculating the quantity of steel in a slab involves understanding slab dimensions, reinforcement percentages, and steel properties. Whether using percentage-based estimation or detailed bar measurements, accuracy is key to efficient construction planning. By following this guide, you can confidently estimate steel requirements, save costs, and maintain structural safety.

For more construction tips and detailed guides, stay tuned to our blog!