Don’t pour that concrete yet! Our essential pre-pour checklist guides you through how to check slab reinforcement for placement, size, cover, and ties to ensure structural integrity and avoid costly fixes

The Final Inspection: How to Check Slab Reinforcement Before Pouring Concrete

That moment before the concrete trucks arrive is charged with anticipation. The formwork is built, and a intricate steel skeleton lies within—the rebar. This reinforcement is the hidden muscle of your slab, giving it the strength to resist cracks, deflection, and failure. Pouring concrete without a thorough rebar check is like building a house on a weak foundation; the problems might be hidden at first, but they are guaranteed to surface.

A proper pre-pour inspection is your single most important quality control step. This guide will walk you through a systematic checklist to ensure your slab’s reinforcement is perfect before the first drop of concrete hits it.

Why This Check is Non-Negotiable

Skipping or rushing this process can lead to:

- Structural Failure: Incorrectly placed rebar can lead to catastrophic slab collapse under load.

- Cracking & Durability Issues: Insufficient concrete cover can lead to corrosion of the rebar, which expands and cracks the concrete from within.

- Costly Repairs: Fixing a misplaced rebar cage after concrete has set is incredibly expensive, often involving demolition and rebuilding.

- Project Delays: Failed inspections or structural remediation can set a project back by weeks or months.

Your Pre-Pour Reinforcement Checklist: A Step-by-Step Guide

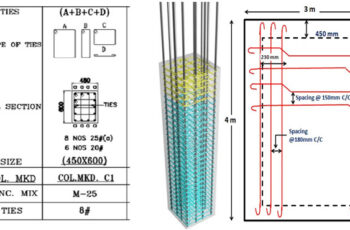

Arm yourself with the structural drawings, a tape measure, a rebar tie wire gauge, and a keen eye. Here’s what to look for.

Step 1: Verify the Rebar Itself (Size, Grade, and Spacing)

This is the “what” of your reinforcement.

- Check the Size (Diameter): Use a caliper or a rebar gauge to confirm the bar sizes match the structural drawings. Are the #5 bars actually #5? Are the #4 dowels really #4?

- Check the Grade: Look for the stamped markings on the bar. A “W” indicates it’s suitable for weldable, low-alloy steel, while “S” is for carbon-steel. The specific marking (e.g., Grade 60) must match the specs. Grade 60 means it has a minimum yield strength of 60,000 psi.

- Check the Spacing: This is critical. Measure the center-to-center distance between the bars. Are the main bottom bars spaced at 8 inches on center as specified? Incorrect spacing directly impacts the slab’s load-bearing capacity. A simple trick is to use a spacing template or a board with marks for quick verification.

Step 2: Inspect Placement and Concrete Cover

This is the “where.” The position of the rebar within the concrete (known as “cover”) is vital for protection and performance.

- Check Bottom Bar Cover: This is the distance from the bottom of the slab to the bottom of the rebar. It protects the steel from moisture and chemicals from the ground. Use a cover meter (a magnetic device) or simply physical measuring blocks placed at regular intervals. Insufficient cover is a leading cause of rebar corrosion.

- Check Top Bar Cover: For two-way slabs or slabs with negative moment reinforcement, the top bars must be held at the correct height from the future finished surface. These are often supported by bolster chairs or continuous high chairs. Ensure they are the correct height and are spaced closely enough to prevent the bars from sagging when workers walk on them.

- Check Clearance from Forms: Ensure no rebar is touching the formwork, as this creates zero cover and a direct path for corrosion.

Step 3: Examine Tying, Splices, and Supports

This is the “how it’s held together.” A well-tied cage stays in place during the concrete pour.

- Check Tie Wire: Are all intersections at least snugly tied? Critical intersections should be double-tied. The cage should be rigid and not “rattle” when walked on. Loose ties can lead to bars shifting during the concrete pour.

- Check Lap Splices: Where two bars overlap to transfer stress, verify the lap length is as per the drawing. Also, check that the bars are properly tied together at the splice.

- Check Supports:

- Chairs & Bolsters: Are they the right type and strength? Plastic chairs for standard slabs, and high-density or steel chairs for heavy loads. Are they spaced adequately (usually 3-4 feet apart) to prevent sagging?

- Beam Cages: Ensure the beam stirrups are vertical, properly spaced, and tied. The main longitudinal bars should be securely held inside the stirrups.

Step 4: Look for Embedded Items and Congestion

The rebar cage doesn’t exist in isolation.

- Check Conduit & Embeds: Ensure all electrical conduits, plumbing sleeves, and anchor bolts are placed correctly and do not conflict with the rebar. Sometimes, a bar may need to be slightly offset (with an engineer’s approval) to accommodate a large pipe.

- Avoid Congestion: In areas with many bars (like around columns), check that there is enough space for concrete to flow through and fully encapsulate the steel. Concrete aggregate cannot pass through gaps smaller than its size, leading to “honeycombing” (voids).

Common Red Flags to Watch For

- Rebar resting directly on the vapor barrier: This eliminates bottom cover. Use concrete “dobies” or plastic chairs to elevate it.

- Sagging top mat: Caused by inadequate chair support. Workers walking on it before the pour will exacerbate this.

- Missing bars or ties: A single missed bar can create a weak point.

- Dirty or rusty rebar: Light, superficial rust is acceptable and can improve bond. Heavy, flaky rust should be removed with a wire brush.

- Damaged chairs or supports: Crushed chairs won’t provide the specified cover.

The Final Walk-Through: Coordination is Key

Just before giving the “all clear,” do a final coordination walk with the project manager, superintendent, and the concrete foreman.

- Cleanliness: Ensure the entire area is clean of debris, mud, and standing water.

- Approval: The engineer or building inspector must have given their formal approval (this is often a legal requirement).

- Communication: Everyone involved in the pour should be aware that the rebar is ready and should not be disturbed.

Referrals for Further Reading

- American Concrete Institute (ACI) 318: Building Code Requirements for Structural Concrete

- What it is: The bible for concrete design and construction in the U.S. It details all requirements for rebar placement, cover, splicing, and more.

- Best for: Understanding the code-backed “why” behind every rule.

- CRSI Manual of Standard Practice

- What it is: Published by the Concrete Reinforcing Steel Institute, this is the industry standard for detailing, fabricating, and placing rebar.

- Best for: Learning standard practices, bar markings, and placement tolerances.

- “The Contractor’s Guide to Quality Concrete Construction” by ASCC

- What it is: A practical guide from the American Society of Concrete Contractors. It’s filled with best practices and photos from the field.

- Best for: Contractors and supervisors looking for real-world, practical advice.

Conclusion: The Ounce of Prevention

The roar of the concrete pump truck is the sound of no return. Once the concrete flows, the position of every bar, chair, and tie is set in stone. A meticulous, 30-minute pre-pour check is the ultimate ounce of prevention. It’s a small investment of time that pays massive dividends in structural safety, project longevity, and peace of mind. Don’t just hope it’s right—know it’s right.

Now, you’re ready to pour.